Data Center Computational Fluid Dynamics (CFD) vs. Real Time Monitoring, Which Makes More Sense?

What is CFD?

Computational Fluid Dynamics, or CFD, is a technique used to model fluid flow using numerical analysis techniques. Through an iterative process, fluid flow is predicted based on how minute volumes, or voxels, interact with each other and surrounding surfaces to create a steady-state, three-dimensional model. Billions of calculations are required to reach this “steady-state. This computational complexity initially relegated CFD to high-end applications such as airplane aerodynamics where design companies could justify the cost of supercomputers to crunch the numbers. Now however, growth in processor power has put CFD modeling into the reach of many industries including data center facilities management.

CFD in the Data Center

Companies such as Innovative Research, Inc. (IRI) have produced CFD modeling software specifically developed for data centers. TileFlow by IRI, offers to model data center airflow to help visualize temperature distribution throughout the data center. Another data center CFD option is Coolsim, a SaaS (Software as a Service) that allows data input at the local level and computation in the cloud. Significant differences in the capabilities of these tools exist and the needs of the data center should be weighed carefully when choosing a simulation tool.

Whether stand-alone software or SaaS solutions are used, the process of CFD modeling for the data center is the same. Geometric data of the modeled space including under-floor obstructions, equipment cabinets, as well as airflow and thermal source/sinks (CRAC in/out, IT equipment in/out) are entered into the software. Once the layout and equipment is set, the software generates a model of the airflow within the data center including temperatures and pressures.

As with any model, the more accurate the information supplied, the more useful the result. Careful attention to detail in both the modeling and construction of new spaces is necessary to insure that the end result matches the model. Un-sealed support column floor piercings, forgotten cutouts under racks, etc. are all insidious paths for air to bypass and potential sources for puzzling results.

Things to Keep in Mind when Considering CFD Analysis

CFD is an excellent tool and in Heath’s opinion, has a critical role in the design of the data center. CRAC failure analysis, potential equipment installations, layout changes, containment, etc. are all very simple to analyze once the initial model has been developed. Of course, the time to employ CFD analysis is before the change is made. Once a row of equipment is in place, operating and getting hot is exactly the wrong time to discover that there is inadequate air flow or excessive recirculation.

The user must always keep in mind that CFD is a snapshot in time and as data centers are dynamic, the CFD model requires maintenance to be useful. Part of the change order process should include an update to the CFD model; so that when a significant change is planned, the model is the most useful to the data center manager in the decision making process.

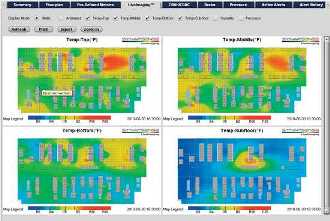

The case for Real Time Monitoring – Visualize the Real World

Real-time monitoring in the data center typically uses wireless sensors to measure environmental conditions including temperature, humidity, pressure differentials and other parameters of interest such as power, intrusion detection, and equipment failure notification. The sensors send the data to a central monitoring application such as SynapSense’s SynapSoft. The software package aggregates the data and then generates color coded, interpolated, real-time thermal, humidity and pressure maps of the data center. Hotspots, areas of overcooling, high/low pressure zones and humidity anomalies are all easily determined. Additionally, many monitoring systems include alarm functions that notify operating staff of situations that may need immediate attention.

The fact that real-time monitoring is dynamic and changes over time makes it very useful for the environmental management of server rooms, especially high density rooms or those approaching the limits of their cooling capacity. By continually monitoring environmental metrics, in-place adjustments to temperature set points, fan speeds, floor tile placement, and aisle configuration can be immediately evaluated for effectiveness. Historical trends aid in the evaluation of the availability of the data center and allow highly available operation while minimizing thermal and airflow margins. This results in optimal energy efficiency.

The Choice Depends on the Need

Both CFD analysis and real-time monitoring have their place in making data center efficiency gains. CFD is clearly the choice for “what if” analysis. Real-time monitoring allows instant evaluation of any changes to the environment. Regardless of the choice however, Heath reminds us, “it necessary to keep in mind that neither real-time monitoring nor CFD analysis save money in and of themselves. Physical changes to the environment such as set point adjustments, CRAC cycling, etc. are made possible by being able to predict and monitor the results. Eliminating un-necessary margin ultimately increases capacity and efficiency, thereby saving money.”

Data Center CFD / Real Time Monitoring Comparison Chart

| CFD | Real-time Monitoring | |

|---|---|---|

| Good For | New design validation, what if analysis, capacity planning. | Overall efficiency analysis, temperature/environmental conditions monitoring, in-place adjustment, trend analysis, and some capacity planning. |

| Ease of Use | Steep learning curve, professional training required for best accuracy. | Relatively simple training. |

| Cost | $$$-$$$$ | $$-$$$$ Expense based on needs. |

| Scalability | Any data center change requires a new CFD analysis. | Easily add more sensors or features. |

| Accuracy | Variable – based on inputs, assumptions, and software used. | Highly accurate at spot-locations, overall accuracy improves with additional sensors. |

| Reliability | Requires careful model validation. | Based on actual real-world data. |

| Adaptability | Static – one time analysis. | Dynamic – tracks changes over time. |

| Potential Efficiency Gains | Substantial for new construction, may require large infrastructure investment. | Substantial when data is acted upon. |

| Potential Uptime Improvement | Dependent on changes made, cannot monitor in real-time, but can help in design. | Substantial when combined with alert systems. |