Information Technology (IT) has an ever-increasing demand for data, space, monitoring, and power consumption. A great deal of current data center power consumption is dedicated to cooling the components so they can keep working at maximum capacity. That consumption will only continue to rise in the coming years. 1 One of the best ways to assist cooling efforts is simple, cheap, elegant, and rudimentary. That solution is implementing blanking panels into the server racks.

What are Blanking Panels?

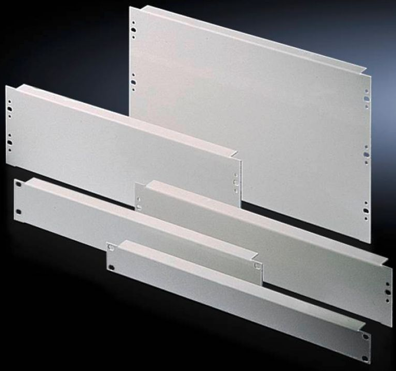

Blanking Panels, also referred to as filler panels by some manufacturers, are a simple modeled pane that is placed over a single unused Rack Unit (RU or simply U) or several RU of a server rack. These panels are easy to snap or screw into place. Their purpose is to optimize airflow so that hot and cold air don’t commingle as the heat rises from the active components within or around the rack. They are modeled to be a vented barrier rather than leaving empty RU in the rack open for air to flow through. That simplicity is why many have overlooked the benefits blanking panels can offer.

By keeping the air separated, it’s easier for the data center to manage the cooling cycle. By keeping the hot air from recirculating, it saves on costs because there is less need for lower set points to compensate for the hot air mixing with cool.

In short, blanking panels are a low-tech solution to meet the physical reality of server rooms’ existence. Now considered a best practice and a must for containment system deployment.2

Historical Context for Blanking Panels

As Data Centers started developing at the end of the last century, they quickly invented and iterated on the idea of using rows for server cooling via airflow. Before this process was ubiquitous, many overlooked the cost of power in use for cooling in the data center and didn’t even consider recirculation costs of warm air mixing with cold air.

“To compensate for the increased temperatures, the increase in fan power for these four servers is about 185 watts. Although this is not an enormous increase (just over 1%) for a rack using nearly 13 kW, the in-creased power adds up over a year. At $0.10 per kW‐hr and a PUE of 2.0, an additional 185 watts results in $324 of added electrical consumption.”6

The use of blanking panels has a significant impact on the amount of unwanted hot exhaust air from the equipment that is recirculated toward the front of the cabinets and then mixed with cold conditioned air available at the equipment air intakes. Covering gaps in a server cabinet leads to a significant reduction of hot exhaust air recirculation. Upsite claims, “the result of using blanking panels to reduce unwanted bypass air within the cabinet significantly reduced and stabilized the temperatures at the server air intakes.”3

The Need for Blanking Panels is Greater Than Ever

The IT industry’s recommendation of using blanking panels has been ubiquitous since the early 2000s. IT equipment manufacturers recognize the benefits of using airflow management blanking panels and advise users of the need to use airflow management blanking panels”3

According to Upsite, a leading manufacturer of blanking panels: “Increasing computing densities have raised IT equipment intake temperatures and increased failure rates, triggering awareness about the importance of effective and efficient conditioned airflow management in computer rooms.”.4

The American Society of Heating, Refrigerating and Air-Conditioning Engineers. (ASHRAE) as well as most major server and storage manufacturers recognize the severity of the power usage being used to cool data centers, and recommend that unused rack space have blanking panels installed to maximize and improve the hot aisle/cold aisle airflow system in the room.5

Blanking Panel Features

One leading choice you can make between different Blanking Panels is which material to use7 points to plastic panels being inexpensive, easy to install, allowing for reasonable control, and assisting with airflow, but overall less durable. While they look to metal panels also allowing for temperate control and helping with airflow; however, the metal panels are more substantial, have sharper edges, are more expensive and harder to install. It would seem that metal panels have faded in popularity for these reasons and should only be implemented if spare RUs will remain blank and static for the foreseeable future.

There are a couple of other differentiations between blanking panels. Some panels need to be screwed in. Others can snap into place on the rack and are referred to as a tool-less solution.

For those in need of increased rack monitoring, the blanking panel temperature strip allows you to see the temperature in a glance to ensure that things are meeting ASHRAE standards.

Then there’s the part you must contend with most regularly after buying – that’s choosing which color you’d like to be staring at, either black or white.

If you require blanking panels, you can find the correct model for your needs on Server Racks Online.

Related Articles

Hot Aisle/Cold Aisle Layout for Data Center Racks

Data Center Rack Cooling Solutions

5 Airflow management questions to ask to improve your Data Center Environment & Save your Budget

References

1. A Simulation-Based Approach to Data Center Thermal Efficiency Optimization by Karman Fouladi and Joseph Schaadt

2. Rack Blanking Panels – To Fill or Not to Fill by David L. Moss and Joyce F. Ruff| Dell

3. Two-Dimensional Computational Fluid Dynamics Analysis of Blanking Panel Solutions by Lars Strong, Kailash C. Karki, and Berkeley T. Merchant | Upsite

4. Blanking Panels Datasheet | Eaton

5. Improving Rack Cooling Performance by Neil Rasmussen | APC

6. A Layman’s Explanation Of the Role Of IT Racks In Cooling Your Data Center By David Moss | Dell

7. Plastic vs Metal Blanking Panels by Justin Mitchell | Lone Star Racks