Improve Energy Efficiency with Hot Aisle Containment while supporting higher density server applications

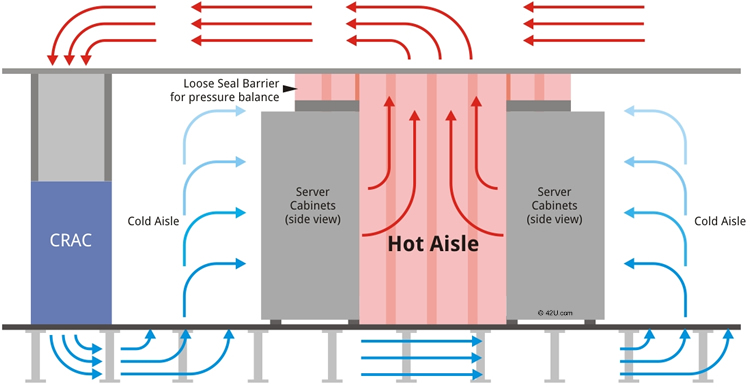

Hot Aisle/Cold Aisle remains a common consideration for data center architects, engineers, and end users. But how much cooling capacity can it really support?

The answer depends on a number of architectural considerations. A number of users have found, however; the approach to be impractical at higher densities, which require high airflow. Bypass air flow problems can cause servers that don’t get sufficient intake air to pull their own exhaust and potentially overheat. And as energy costs continue to rise, the practice of producing and driving larger volumes of cold air to compensate for these hotspots is wildly inefficient.

The answer depends on a number of architectural considerations. A number of users have found, however; the approach to be impractical at higher densities, which require high airflow. Bypass air flow problems can cause servers that don’t get sufficient intake air to pull their own exhaust and potentially overheat. And as energy costs continue to rise, the practice of producing and driving larger volumes of cold air to compensate for these hotspots is wildly inefficient.

The high density installations of blade servers are causing hot spots and cooling these blades is a significant airflow distribution problem. One of the most recommended best practice solutions to resolve this problem is containment-the complete separation of the air paths on the data center floor. Hot Aisle Containment, for this reason, succeeds as an efficiency strategy. Server exhaust air, so often the culprit in conventional cooling, is removed from the room at large. Users can then focus cooling strictly to the rack or row.

What is Hot Aisle Containment?

Depending on the manufacturer, these solutions may or may not include fans to propel the air out of the cabinet and in to the false ceiling.

Hot Aisle Containment Configuration

One version of hot aisle containment turns the hot aisle into its own room. Once cabinets are aligned in the traditional hot aisle/cold aisle layout, the hot aisle is sealed with doors, sidewalls, and roofs.From there, an In-Row air conditioner takes over. This unit, more compact, is embedded within a row of enclosures. It captures exhaust air off the equipment, conditions it, and returns it to the cold aisle.

This approach involves a specialized cabinet with a solid rear door and attachments for ductwork (also called a chimney) and a false ceiling. Attached to the rear of the server cabinets, these ducts catch the exhaust air off the servers and channel it into a false ceiling.The false ceiling serves as a plenum, delivering the hot exhaust air to a perimeter-mounted air conditioner, which may also extend, via ducts, to the ceiling level.

Hot Aisle Containment: Efficiencies

Hot Aisle Containment Installation

Intel’s “The State of Data Center Cooling” whitepaper states the following: “Hot aisle containment or chimney cabinets generally are more forgiving and efficient in a greenfield design.” Here are some key considerations:

The In-Row air conditioner functions like a traditional CRAH in a smaller footprint; it brings to the cooling directly to the row or rack level. Like its counterpart, it requires a chilled water connection. Existing facilities must consider the feasibility of bringing chilled water to the desired location for the AC unit.

- If the chilled water infrastructure consists of hard or copper piping, how complex is the addition of new piping lines?

- How does it fit into the broader cooling architecture?

- Will it necessitate downtime or can it be deployed within a live environment?At the row level, will existing cabinet rows need to be rearranged to incorporate the AC?

- Will it work with existing cabinets or require new ones, meaning equipment has to be removed and re-racked?

At the room level, existing facilities must first have a drop ceiling with a logical return air path to the air conditioner intake. From there, users need to consider compatibility with the existing parts and pieces.

- Is the ceiling and/or false ceiling height compatible with the ductwork?

- Would the chimney installation interfere with existing ladder rack, cable runs, or power drops?

- What modifications are necessary to existing cabinets to install the ductwork?

- Are the ducts only compatible with proprietary cabinet solutions?

- How complex is the overall installation in a production data center?

Greenfield facilities can plan for everything during the design phase. For legacy sites, the concerns above may or may not be deal breakers. It becomes complicated when existing cabinets, rows, and infrastructure need to be reworked in a production environment.

Conclusion

For users with suitable designs, Hot Aisle Containment offers marked efficiencies over conventional HVAC cooling.

- Certain In-Row air conditioners, used to contain the exhaust air, are equipped with variable speed fans, which align with the compute load. For fans, speed is directly related to energy consumption: If you can reduce fan speed by 10%, fan power consumption decreases by 27%. If you reduce fan speed by 20%, fan power drops by 49%” (Fontecchio, 2009).

- Instead of addressing an entire room, hot aisle containment (the room within a room) focuses cooling strictly on that load. Right-sizing instead of over or under-cooling will have a significant impact on the cooling portion of PUE.

- A hosting facility, using chimney-based containment, estimates they will save 25% to 30% in their annual energy bill, resulting in savings of $250,000 to $300,000 (McLawhorn, 2009).

- With server exhaust controlled, both flavors of containment allow for warmer temperature settings, which can permit more use of air-side and water-side economizers. Considering “data center managers can save 4 percent in energy costs for every degree of upward change in the set point” (Miller, 2007), the practice is good for the bottom line and good for the environment.

The Green Grid sees an air management strategy as “the starting point when implementing a data center energy savings program.” Hot aisle containment succeeds as an efficiency strategy because of its far reaching effect on the entire data center from the inlet temperature, to the air conditioners, to the chiller plant.

Read More about Hot Aisle Containment Layouts

References

Fontecchio, M. (2009, January 21). Data Center Air Conditioning Fans Blow Savings Your Way. Retrieved January 22, 2009, from Search Data Center: http://searchdatacenter.techtarget.com/news/article/0,289142,sid80_gci1345584,00.html

Intel. (2008, March). The State of Data Center Cooling. Retrieved February 12, 2009, from Intel: http://download.intel.com/technology/eep/data-center-efficiency/state-of-date-center-cooling.pdf

McLawhorn, N. (2009, February). Passive cooling solution reduces energy expenses. Retrieved February 19, 2009, from Cabling Installation and Maintenance: http://cim.pennnet.com/display_article/352690/27/ARTCL/none/none/1/Passive-cooling-solution-reduces-energy-expenses/

Miller, R. (2007, September 24). Data Center Cooling Set Points Debated. Retrieved February 19, 2009, from Data Center Knowledge: http://www.datacenterknowledge.com/archives/2007/09/24/data-center-cooling-set-points-debated